Complete set of Rice milling plant

Brand Golden Grain

Product origin China

Delivery time 30 Working Days

Supply capacity 100sets/month

1.The rice milling machine has a beauty installation structrure.

2.The rice milling machine has high out rate of rice guarantee.

3.The rice milling machine needs Less Worker labor.

4.The rice milling machine has high production effciency.

30Tons to 400 Tons Per Day Rice Mill Plant

Procduction introduction of rice mill plant

1. This complete rice mill machinery (rice mill plant)cover an area of an area small, small investment, and apply the latest technology of rice milling, improve the milled rice rate, reduce broken, lower temperature meters, good bran removal effect, stable mechanical performance, convenient operation and maintenance.

2. Every major operation unit of rice mill machiney is driven by an indepandent ganerator, which is controlled by an independent control panel.

3. Craft work can be designed specially, combined flexibly and processed into different kinds of excellet rice according to different client's need.

4. The rice mill machinery is coated with a technique of static spray coating; the coating looks smooth and finr and is Weatherproof.

5. The feeding pipes are made of smooth glass, which looks good and very durable, too.

6. What's more, it is environment-friendly inters of adopting high-effective dust collecting unit to get rif of dust.

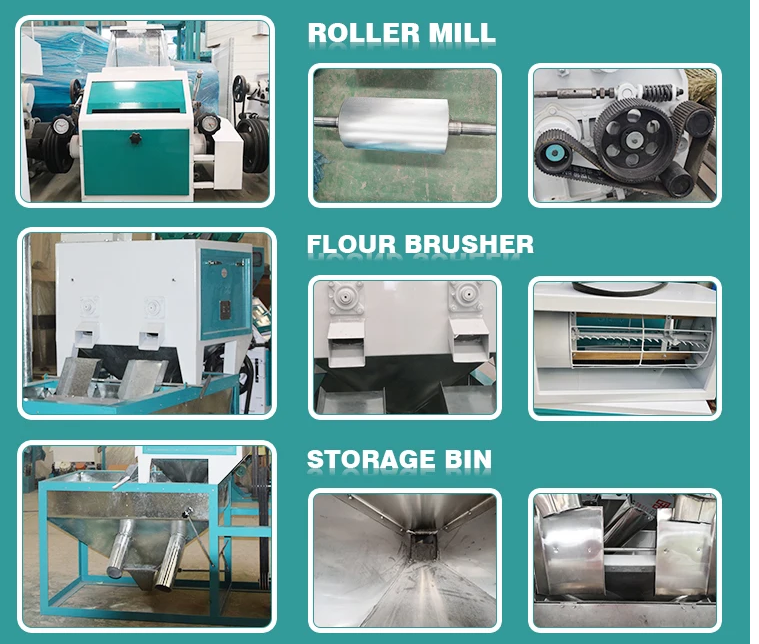

Details of rice mill machinery

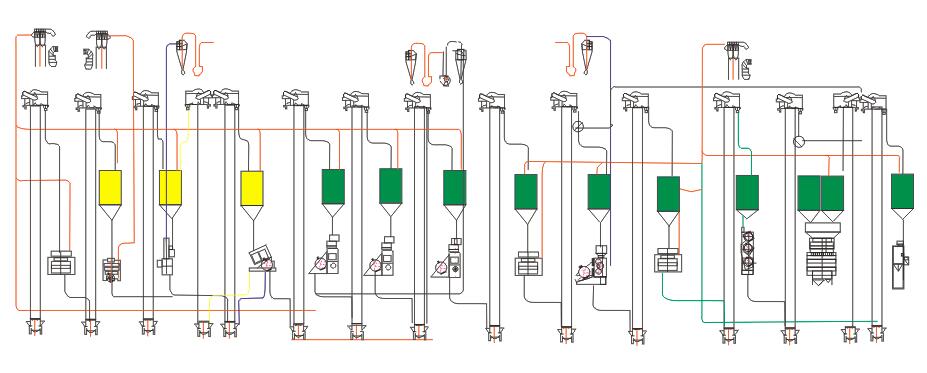

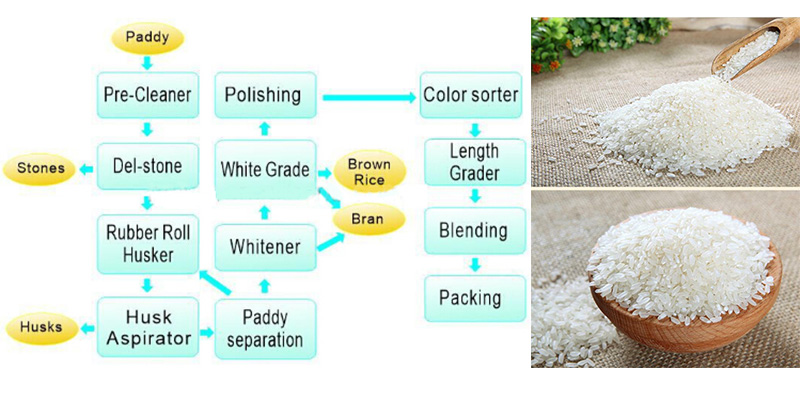

Flow chart of rice mill plant(rice mill machinery)

Paddy Cleaner → Destoner → Paddy husker → Paddy Separator → Rice Whitener → Water Polisher → Rice Grader → Color Sorter → Packing

Rice processing steps

1. Pre-cleaning: removing all impurities and unfilled grains from the paddy

2. De-stoning: separating small stones from the paddy

3. Husking: removing the husk from the paddy

4. Husk aspiration: separating the husk from the brown rice/unhusked paddy

5. Paddy separation: separating the unhusked paddy from the brown rice

6. Whitening: removing all or part of the bran layer and germ from the brown rice

7. Polishing: improving the appearance of milled rice by removing remaining bran particles and by polishing the exterior of the milled kernel

8. Sifting: separating small impurities or chips from the milled rice

9. Length grading: separating small and large brokens from the head rice

10. Blending: mix head rice with predetermined amount of brokens, as required by the customer

11. Weighing and bagging: preparing milled rice for transport to the customer

Product features and application or rice mill machinery

1.The rice mill machinery has a beauty installation structrure.

2.The rice milling machine has high out rate of rice guarantee.

3.The rice milling machine needs Less Worker labor.

4.The rice milling machine has high production effciency.

Packing&Delivery of rice mill plant

Packaging Details

1. We will pack all single machine with the plastic film.

2.Fix the rice mill machinery on the container for the safety of long-time transportation of goods.

3.Some special unit of rice mill plant will be putted into the box to avoid any damage or missing.

4.Small parts of rice mill plant will be putted into the bags, boxes or make special packaging.

5. According to customer requirements, each rice mill mchinery is labeled with name and quantity.

Port:Dalian,China.

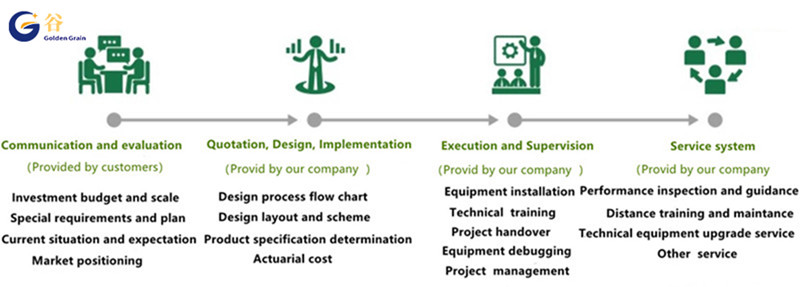

Our cooperation with foreign clients

If you have any questions, welcome to contact us!

Company information

Liaoning Golden Grain Grain and Oil Machinery Co., Ltd(Formerly known as Zhengshuanghuan General Equipment Manufacturing Co.,Ltd)was established on August 30,1992 in Shenyang, China.

Our company has nearly 30 years professional experience in manufacturing Grain Machinery,the main products includes :Maize Milling Machine,Rice Milling Machine,Wheat Flour Milling Machine,Sorghum Milling Machine,Millet Milling Machine and Oil Refining Machine.

Factory covers an area of 20000 square meters, 6000squrare meters office building area,owns high quality standard heavy industrial production workshops.

Employees includes medium and senior professional management personnel, engineering technical personnel and professional foreign trade team sales staff.

We design products according to customers’ specific requirements with carefully installation and technical training. Products have been exported to many countries such as:Russia,North Korea. Viet Nam, Nigeria, South Africa, and Southeast Asia. We are willing continue to expand our business around the world.