Flour Purifier

Brand Golden Grain

Product origin China

Delivery time 3-7 Working Days

Supply capacity 100sets/month

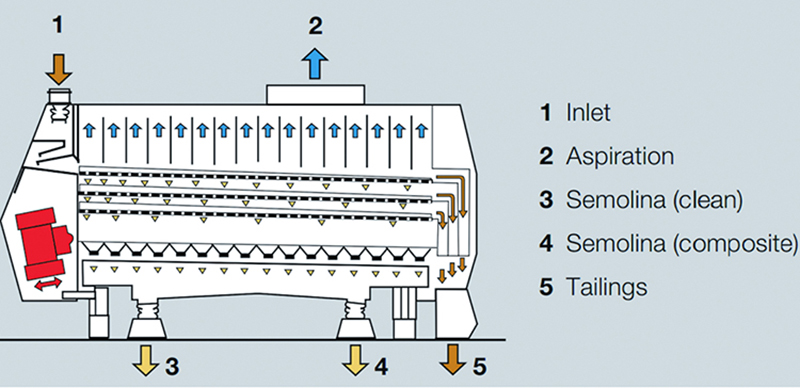

1.purifier for wheat mill plant and grading of coarse flour and intermediate materials in the process of coarse flour, flour or corn.

2.The evenly flowing materials are distributed in the full width of the purifier for wheat mill plant screen surface through the feeding door.

3. purifier for wheat mill plant screen grid of flour purifier is divided into three layers. The air flow of the materials in the screen is from top to bottom, lifting the lightest particles and sucking them away by the air flow through the ventilation hood.

purifier for wheat mill plant

corn flour purifier introduction

corn flour purifier Working principle and features

corn flour purifier is our newly designed product. corn flour purifier has the following features:

corn flour purifier has complete in specifications, elegant appearance.

High yield: wider sifter can improve the processing capacity 20%, and we can stack up two purifiers together so as to get higher production capacity.

Safety and sanitation: corrosion-resistant material protects the end products from any pollution. Complete sealing structure can ensure the sanitary standard. Ichthyoid air suction system and modified air distribution makes operation sanitary.

Low production and operation cost, accurate air volume control: integrated for of LED illumination offers excellent lighting for screen and reduces energy consumption.

Perfect design in economical efficiency and functionality. corn flour purifier

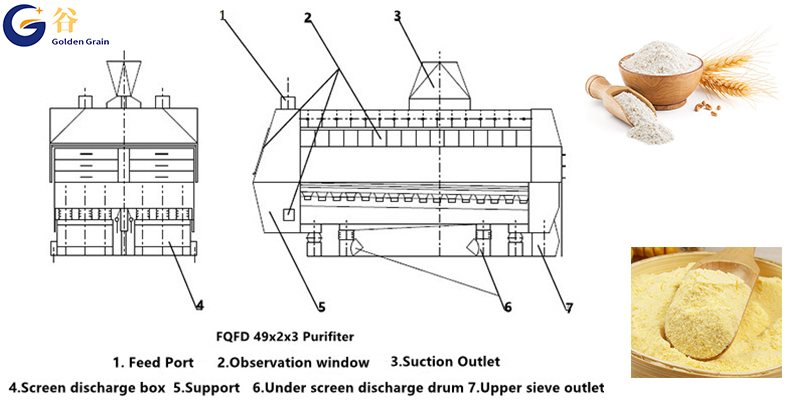

corn flour purifier parameters

Parameters

Specification | Productive capacity | Power (kg) | Corner of glory | Air volume | Weight | Dimension | ||

Thick | Thin | Fore-end | Back-end | |||||

FQFD 60x2x3 | 1800-3500 | 1200-2000 | 2x0.25 | 10-15 |

5-15

| 55-90 | 1100 | 2700x1400x1675 |

FQFD 49x2x3 | 1200-2600 | 800-1600 | 2x0.18 | 40-70 | 970 | 2700x1400x1675 | ||

corn flour purifier features and application

① Each layer of sieve lattice is drawer type, which can be pulled out or loaded one by one, and pressed in the longitudinal direction;

② The four sides of the screen lattice are equipped with a device to tighten the screen surface, which can quickly replace the screen surface. When the screen surface tension is reduced, it can continue to work for 2 to 3 times.

Packing&Delivery

Packaging Details

1. We will pack all single machine with the plastic film.

2.Fix the machine on the container for the safety of long-time transportation of goods.

3.Some special unit will be putted into the box to avoid any damage or missing.

4.Small parts will be putted into the bags, boxes or make special packaging.

5. According to customer requirements, each product is labeled with name and quantity.

Port:Dalian,China

Our cooperation with foreign clients

Company information

Liaoning Golden Grain Grain and Oil Machinery Co., Ltd(Formerly known as Zhengshuanghuan General Equipment Manufacturing Co.,Ltd)was established on August 30,1992 in Shenyang, China.

Our company has nearly 30 years professional experience in manufacturing Grain Machinery,the main products includes :Maize Milling Machine,Rice Milling Machine,Wheat Flour Milling Machine,Sorghum Milling Machine,Millet Milling Machine and Oil Refining Machine.

Factory covers an area of 20000 square meters, 6000squrare meters office building area,owns high quality standard heavy industrial production workshops.Employees includes medium and senior professional management personnel, engineering technical personnel and professional foreign trade team sales staff.

We design products according to customers’ specific requirements with carefully installation and technical training. Products have been exported to many countries such as:Russia,North Korea. Viet Nam, Nigeria, South Africa, and Southeast Asia. We are willing continue to expand our business around the world.

If you have any questions, welcome to contact us!