Importance of Rice Milling Machine in Rice Factory

Importance of Rice Milling Machine in Rice Factory

Rice milling is a process of stripping off all the cortex on the surface of brown rice, and keeping the rice grains as complete as possible while achieving a certain processing accuracy.

1. Basic requirements for rice milling:

Under the premise of ensuring that the processing accuracy of the finished rice meets the specified standards, the rice grain is kept intact as much as possible, the broken rice is reduced, the yield is increased, the purity is improved, the power consumption and cost are reduced, and safe and stable production is ensured.

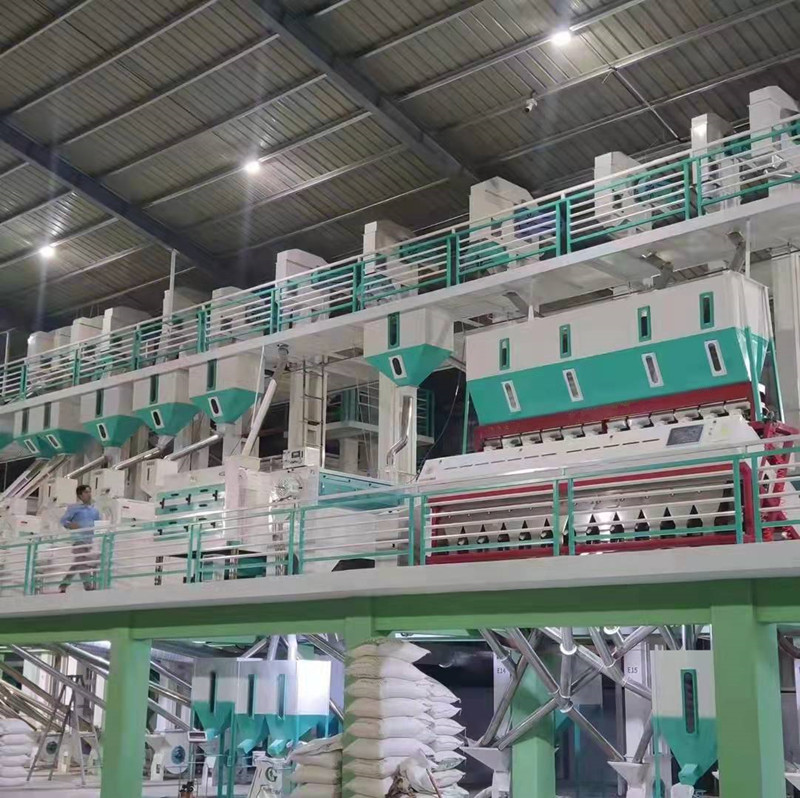

Rice milling machine is a method of peeling and whitening rice by using the mechanical force generated by mechanical equipment. The mechanical equipment used is called rice milling machine. The main working part of the rice mill is the roller. According to the different manufacturing materials, rollers are divided into three types: iron rods, sand rollers and sand iron. According to the installation form of the roller shaft, the rice milling machine is divided into two types: vertical rice milling machine and horizontal rice milling machine. Depending on the number of rollers, rice mills can be divided into single-roller and double-roller or three-roller combined rice mills.

2. Rice milling process

The main task of the rice milling section is to grind off most or all of the surface layer of brown rice to make finished rice that meets the standard. Because rice milling directly processes rice grains, it directly affects the yield and quality of finished rice.

The rice milling section is mainly divided into two parts: rice milling and finished product processing. It goes without saying that whitening brown rice is the most important process in the rice milling section. After the rice is milled, bran powder is often stuck on the surface of the rice grains, and broken rice is mixed between the rice grains and the rice grains. In addition, when processing high-quality rice, it is also necessary to polish the surface of the rice grains to remove yellow-grained rice and other different-colored rice grains. Therefore, the finished product must be processed after brown rice is milled.

3. How to choose rice milling equipment

The tasks undertaken by each process of the rice mill are completed by a certain processing equipment. Whether the equipment is properly selected or not should not only directly affect the process effect, but also affect various economic and technical indicators of the rice mill. When selecting equipment, we should try to use advanced equipment with good process effect, simple structure and convenient operation according to the collected and sorted information. According to the characteristics of the raw grains and the requirements in the technological process, the equipment with standardization, serialization and generalization of parts and components is preferred. Under the condition of capital permission, some main equipments, especially rice milling and finished product processing equipment, can also be appropriately introduced. When selecting equipment, the conveying method of the material should also be considered. When using pneumatic conveying, the role of one wind for multiple purposes should be considered, so that (feeder, unloader) can replace the role of some processing equipment, and simplify the part of some equipment that needs to be sucked to save power and reduce materials and materials consumption. In addition, the equipment layout and operation requirements should also be considered when selecting equipment, so as to facilitate other designs after the process design is completed, so that the newly built or rebuilt plant can achieve safe and civilized production.