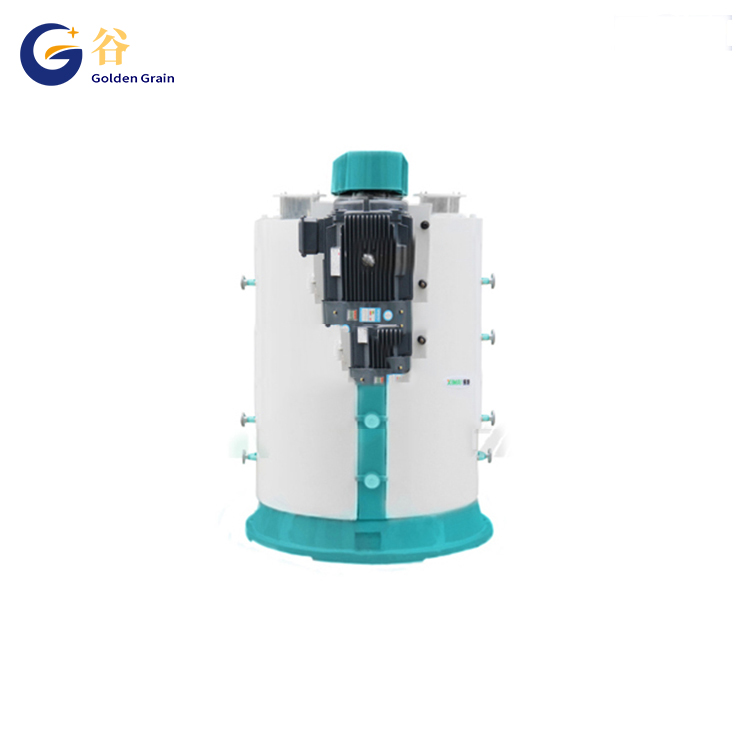

Maize Degerminator Machine

Brand Golden Grain

Product origin China

Delivery time 3-7 Working Days

Supply capacity 100set/month

1.corn degerminating machine is flexible de embryo process to realize economic value.

2.corn degerminating machine by adjusting the gap between the washboard and the toothed board, the dehermination rate of corn with different humidity and density can be maintained, so as to increase the yield of main products.

3.corn degerminating machine full dry degerming, low fat content, reduce energy consumption and equipment costs.

corn germ removing machine

corn germ removing machine introduction

The corn germ removing machine is ideal equipment for degerming in the corn deep-processing enterprises, the alcohol processing enterprises, corn oil companies, and feed processing enterprises. corn germ removing machine complete set of semi dry and dry corn processing projects, separation equipment of corn germ and endosperm, corn germ removing machine improving the quality of corn processing and improving the value of corn processing auxiliary products.

corn degerminating machine working principle

corn germ removing machine destroy the structure of corn endosperm, as well as the structural strength of corn embryo and the bonding

strength of endosperm and germ under the combined action of the strike cutting and centrifugal impact between the rotor and the tooth plate,

and the collision and friction between corn grains, so as to achieve the purpose of peeling, dehulling and grits breaking.

corn germ removing machine less fine materials, stable product quality. Because the processing process of corn raw grain is in line with the corn structure,

it can effectively separate the germ, epidermis and endosperm, and reduce the production of flour and the loss of endosperm.

Thus, corn germ removing machine finished product with high purity and integrity can be obtained.

corn degerminating machine parameters

Specification | DTP75*100 |

Yield(t/h) | 4-5 |

Rotor diameter(mm) | 710-740 |

Striking speed(m3) | 18-19 |

Electric motor(kw) | 18.5 |

DimensionsL*W*H(mm) | 1450*1140*2030 |

Equipment weight(kg) | 1500 |

corn degerminating machine features and application

Flexible de embryo process to realize economic value.

By adjusting the gap between the washboard and the toothed board, the dehermination rate of corn with different humidity and density can be maintained, so as to increase the yield of main products;

Full dry degerming, low fat content, reduce energy consumption and equipment costs.

The endosperm of DTP corn kneading and degerming machine with dry degerming process contains lower fat.

In dry degerming, the product does not need to moisten grain and contact with water. Compared with wet degerming, the whole process is more hygienic, and the energy consumption and equipment expenditure of drying equipment are reduced.

If DTP corn kneading and degerming machine adopts full dry degerming method, it can provide more benefits for users: the product does not need to moisten grain and contact with water.

Compared with wet degerming, the whole process is more sanitary, and the energy consumption of drying equipment is reduced, and the operation cost and investment cost are reduced.

Packing&Delivery

Packaging Details

1. We will pack all single machine with the plastic film.

2.Fix the machine on the container for the safety of long-time transportation of goods.

3.Some special unit will be putted into the box to avoid any damage or missing.

4.Small arts will be putted into the bags, boxes or make special packaging.

5. According to customer requirements, each product is labeled with name and quantity.

Port:Dalian,China

Our cooperation with foreign clients

Company information

Liaoning Golden Grain Grain and Oil Machinery Co., Ltd(Formerly known as Zhengshuanghuan General Equipment Manufacturing Co.,Ltd)was established on August 30,1992 in Shenyang, China.

Our company has nearly 30 years professional experience in manufacturing Grain Machinery,the main products includes :Maize Milling Machine,Rice Milling Machine,Wheat Flour Milling Machine,Sorghum Milling Machine,Millet Milling Machine and Oil Refining Machine.

Factory covers an area of 20000 square meters, 6000squrare meters office building area,owns high quality standard heavy industrial production workshops.Employees includes medium and senior professional management personnel, engineering technical personnel and professional foreign trade team sales staff.

We design products according to customers’ specific requirements with carefully installation and technical training. Products have been exported to many countries such as:Russia,North Korea. Viet Nam, Nigeria, South Africa, and Southeast Asia. We are willing continue to expand our business around the world.

If you have any questions, welcome to contact us!