20 Tons Per Day Corn Processing Equipment

Brand Golden Grain

Product origin China

Delivery time 15 working days

Supply capacity 100sets/month

1.Corn processing equipments can save labor costs, usually one person can be available for operation.

2.Complete function processing as cleaning maize, peeling maize, and grinding maize into maize flour and maize grits.

3.Corn processing equipments clean maize to remove stone, metal, sand and all sorts of impurities.

4.Corn processing equipments peel maize to remove maize skin, remove maize germ, remove black maize . After cleaning and peeling, it prepares best maize material for further processing into maize flour or grits.

5.You can choose the mesh to make the flours fine as you requirement.

20 Tons Per Day Corn Processing Plant

Product introduction of corn processing plant

The Corn milling plant(The milling machine)designed by our company has advanced technology, which can produce different corn kernels, flour and corn husk at the same time, with high yield and good quality. This technology of corn grinding mill is an ideal choice for food factory, alcohol factory, wine factory, lactic acid factory, corn sugar factory and other corn processing enterprises.

This corn porcessing plant(corn grinding mill )Using dry corn processing technology, the dehumidification rate of skin embryo reached 95%. The corn deep processing machine can produce refined corn flour (fine taste, fineness up to 120 mesh) and a variety of corn grains (corn grits). Corn germ, corn skin and other products.

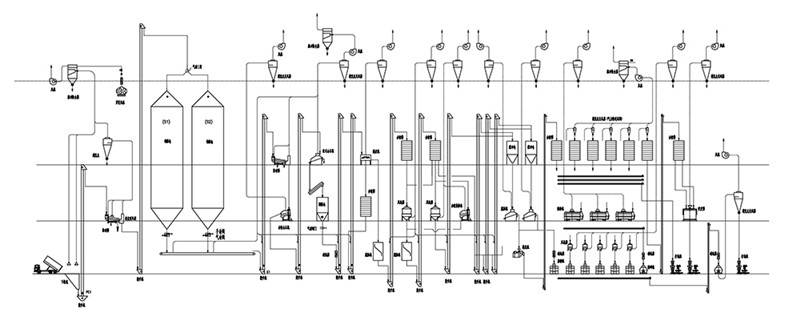

Processing flow chart of corn processing plant(corn grinding mill)

Product parameters of corn milling machine(corn grinding mill)

| Corn Milling Machine Specifications | |||||||

| Type | 20T | 30T | 50T | 80 T | 100T | 150T | 200T |

| Capacity(t/d) | 20 | 30 | 50 | 80 | 100 | 150 | 200 |

| Power(kw) | 72 | 97 | 154 | 197 | 280 | 360 | 460 |

| Installation Area(m) | 11*5.5*5 | 12*5.5*5 | 15*5.5*5 | 16*8*7 | 22*8*9 | 26*8*10 | 28*12*12 |

Product features and application of corn grinding mill

1. Compared with the whole set of wet corn processing technology, the corn processing plant investment of moistening grain in the early stage and drying finished products in the later stage is reduced;

2. Corn dry processing technology, material processing process without contact with water, processing more sanitary, more concise, more labor-saving;

3. The corn processing plalnt using peeling equipment to reduce the loss of endosperm in the process of peeling;

4. The corn milling plant has streamline modular design, the use of grain cleaning, two peeling, a polishing process, the whole process automation.

5. The main parts of thecorn grinding mill (corn milling plant)are made of alloy materials that meet the export standards, which not only ensures the production efficiency, but also takes into account the long-term stability of the equipment, so that users do not spend more money on maintenance.

Packing&Delivery of corn processing plant

Packaging Details

1. We will pack all single machine of corn milling machine(corn processing plant) with the plastic film.

2.Fix the corn milling machine on the container for the safety of long-time transportation of goods.

3.Some special unit of corn grinding mill(corn milling machine) will be putted into the box to avoid any damage or missing.

4.Small parts of corn processing plant(corn milling machine) will be putted into the bags, boxes or make special packaging.

5. According to customer requirements, each product of processing plant (corn milling machine)is labeled with name and quantity.

Port:Dalia,China

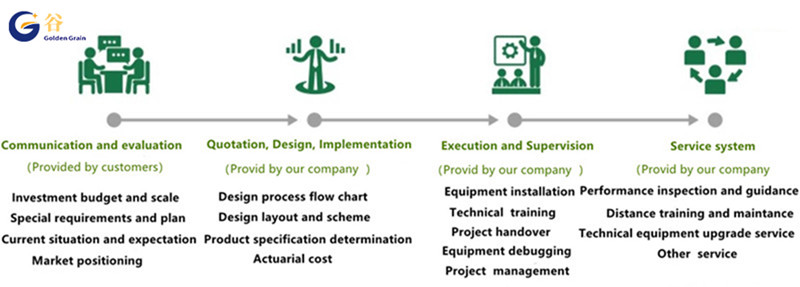

Our cooperation with foreign clients

If you have any questions, welcome to contact us!

Company information

Liaoning Golden Grain Grain and Oil Machinery Co., Ltd(Formerly known as Zhengshuanghuan General Equipment Manufacturing Co.,Ltd)was established on August 30,1992 in Shenyang, China.

Our company has nearly 30 years professional experience in manufacturing Grain Machinery,the main products includes :Maize Milling Machine,Corn grinding mill,Rice Milling Machine,Wheat Flour Milling Machine,Sorghum Milling Machine,Millet Milling Machine and Oil Refining Machine.

Factory covers an area of 20000 square meters, 6000squrare meters office building area,owns high quality standard heavy industrial production workshops.Employees includes medium and senior professional management personnel, engineering technical personnel and professional foreign trade team sales staff.

We design products according to customers' specific requirements with carefully installation and technical training. Products have been exported to many countries such as:Russia,North Korea. Viet Nam, Nigeria, South Africa, and Southeast Asia. We are willing continue to expand our business around the world.